Comparing Aluminum vs. Galvanized Steel Ammonia Evaporators for Freezers

“THE ALUMINUM ADVANTAGE”

Bruce I. Nelson, P.E., President

Colmac Coil Manufacturing, Inc.

Background

Air-cooling evaporators used in ammonia freezer systems have traditionally been made using galvanized (zinc-coated) carbon steel. Other metals are compatible with ammonia, including stainless steel and Aluminum. Designers and installers of industrial ammonia freezer evaporators for low-temperature applications must be concerned with the weight, performance, and reliability of the equipment being specified. Additionally, there may be requirements for corrosion resistance, cleaning, and defrosting characteristics that must be considered. Ammonia and Aluminum are compatible and have been used in ammonia heat exchangers for several decades. The properties of Aluminum make it an ideal metal for ammonia refrigeration applications. This article will describe those properties and compare them to galvanized steel, another commonly used combination of metals used for ammonia heat exchangers, to clearly show The Aluminum Advantage.

Comparison of Properties:

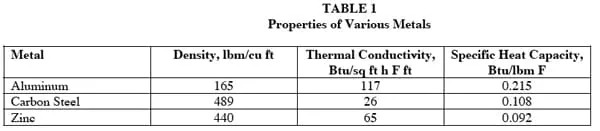

Table 1 below compares several properties of Aluminum to those of carbon steel and zinc. Galvanized steel is obtained by dipping carbon steel in a bath of molten zinc. This is why the table shows these two basic metals.

The Density of the metal directly affects the weight of the heat exchanger, and when multiplied by the Specific Heat Capacity, the product indicates the amount of energy required to heat up and cool down the heat exchanger during a defrost cycle. The Thermal Conductivity of the metal affects the thermal performance of the heat exchanger, and the speed and effectiveness of defrost.

Advantage: Weight

The very low density of aluminum compared to steel and zinc results in a much lighter heat exchanger. A galvanized steel ammonia evaporator will weigh 3 times more than an aluminum evaporator having the same dimensions. The higher Thermal Conductivity of aluminum results in better thermal performance compared to galvanized steel. When the effect of increased performance with aluminum is considered, the galvanized steel version will weigh 3 ®ˆ times more than an aluminum evaporator having the same cooling capacity. The lighter weight of aluminum evaporators reduces structural requirements for buildings where units are ceiling hung, an especially important feature in high seismic areas. Rigging and handling are also made easier with lighter weight aluminum evaporators. It is easy to visualize the advantages of mounting a 2,000 lbs. aluminum evaporator compared to a 6,000 lbs steel evaporator in a room with a 30-foot ceiling.

Advantage: Performance

The Thermal Conductivity of aluminum is 4 times higher than steel, and 2 times higher than zinc. Thermal Conductivity has a direct effect on heat transfer efficiency, the higher, the better. Aluminum is superior to galvanized steel for efficient heat transfer. Tests have proven conclusively that an ammonia evaporator made with aluminum tubes and fins will have a cooling capacity that is 12 to 15% higher than a galvanized steel evaporator having the same dimensions. The superior cooling capacity of aluminum evaporators allows the designer the choice between (a) selecting an evaporator having fewer rows and/or wider fin spacing for lower first cost, or (b) using the same size unit (same rows and fin spacing) and operating at higher suction pressures with resulting reduced operating costs, compared to galvanized steel.

Advantage: Freezer Defrost

The much higher Thermal Conductivity of aluminum (4 times higher than steel) will also result in faster, more effective defrosts. Aluminum evaporators simply defrost faster and better than galvanized steel coils. Also, a substantial amount of energy is expended during defrost to heat the mass of metal in a refrigeration evaporator up to the melting point of ice (32 F), then to cool the metal back down to operating temperature. When the Density of the metal is multiplied by the Thermal Conductivity, the resulting product indicates the amount of energy required to heat or cool a heat exchanger of a given volume by one degree. Based on this analysis, a galvanized steel evaporator will require 70% more energy than the same size aluminum evaporator to heat up and cool down during every defrost cycle. This component of defrost energy becomes very significant at lower temperatures (i.e. in freezers). Using aluminum evaporators can produce significant savings in operating costs over the course of a year, especially at freezer temperatures

Advantage: Corrosion Resistance

Pure ammonia naturally passivates aluminum surfaces. The passivation process cleans the surface of the metal of impurities and promotes the formation of the normal protective oxide layer. Thousands of industrial aluminum ammonia evaporators have been installed and operated successfully since the 1970s. Corrosion of heat exchangers by contact with, or proximity to, foodstuffs is a concern in food processing facilities. All foodstuffs are mildly acidic. Aluminum is more corrosion resistant than galvanized steel when exposed to acetic and citric acids (dairy products, citrus products), fatty acids (anti-caking agents, lubricants), and lactic acids (bread, confections, beverages, fermentation, blood). Aluminum is more corrosion resistant than galvanized steel in the presence of sodium chloride (preservation of meats and vegetables), and sulfur dioxide (grape storage). Neither galvanized steel nor aluminum is recommended for exposure to nitrites (cured and smoked meats). Stainless steel is the suggested material to use in the presence of nitrites. Generally speaking, aluminum is a better metal to use than galvanized steel where there is concern about corrosion due to contact with most foodstuffs.

Advantage: Freezer Cleanability

Cleanability of freezer equipment in food freezer processing facilities, including evaporators, has become an increasingly important issue, especially when it comes to food freezers. Bacterial contaminants must be removed with regular cleaning, and locations where they can accumulate need to be minimized. The smooth, hard surfaces of aluminum evaporators are ideal for effective cleaning in food processing equipment and facilities. The rough, porous surfaces of galvanized steel evaporators may present difficult cleaning problems for operators in facilities where bacteria-free operation is critical. Another issue of importance is the effect of various cleaners on aluminum and galvanized steel.

There are four basic types of cleaners used in the food freezer processing industry:

- Acidic

- Strongly Alkaline

- Mildly Alkaline

- Chlorine Based

Both aluminum and galvanized steel are attacked by Acidic, Strongly Alkaline, and Chlorine-based cleaners. These types of cleaners are not recommended for use on any ammonia evaporators. A foaming type Mildly Alkaline cleaner (such as Base-511 manufactured by Great Western Chemical) is recommended for both aluminum and galvanized steel surfaces. If Caustic Soda (Strong Alkaline) must be used for clean up, then galvanized steel is preferred over aluminum, since zinc has higher resistance than aluminum to mildly alkaline solutions. Advantage: Colmac Reliability Since 1984, Colmac has successfully manufactured all-aluminum evaporators for ammonia refrigeration systems. Only the best quality, heavy-wall, seamless drawn, 3003 alloy aluminum tubing is used. 100% of this tubing is eddy current tested at the Colmac factory before assembly into evaporators, insuring zero-defects. All tube joints are carefully joined by a special TIG welding process, then pressure tested at 500 psi to insure absolutely no leaks. The result of this rigorous quality manufacturing program is zero leaks in any tube or welded joint on start-up on any Colmac all-aluminum ammonia evaporator ever made!

REMEMBER When you want to specify Quality, specify Colmac for freezers

The More You Know About Freezers

The More You Will Look To Advanced Equipment Inc. as Your Reliable Supplier.

BENEFITS

- Packaged and fully tested at our factory before shipping.

- Fully Seamless Welded Insulated Enclosure.

- Exterior Direct Drive System.

- Ready to be placed and connected to refrigeration, electrical and water service.

- Built to USDA, FDA, UL, CFIA, OSHA and CSA - Specifications & Standards

- Self Cleaning with internal center drum washer manifold as standard feature.

- Continuous inline food freezing.

- Gentle, smooth handling of products.

- Compact packaged design in lower operation cost and saving process floor space.

- High-efficiency impingement horizontal airflow, allowing fast freezing.

- Minimum product weight loss by exposure to the coldest air temperature at all time for each tier directly from evaporator.

- Stainless-steel construction.

- Easy access to sanitation and maintenance.

- Customizable design to fit requirements.

LOW OPERATION COST

IQF Spiral Freezers are low operation cost compared to C02, nitrogen and other freezers. This is achieved by utilizing the most efficient mechanical refrigeration method, combined with our new unique low-pressure, high velocity, impingement horizontal airflow recirculation system. The horizontal airflow assures the coldest air continuously removes heat from all surfaces of the product.

Each tiers of product directly receives the recirculated coldest air off a refrigerated -40C evaporator.

ECONOMICAL

One of the most economical freezer offered in its class. Every component of the freezer is manufactured in our well-equipped engineering and manufacturing facility; we can afford to pass on the savings to our customers, without sacrificing quality.

CUSTOM DESIGN

ADVANCED EQUIPMENT INC. begins with a standard design that is carefully customized to meet most standard needs. However, we can also custom design our equipment to individual customer’s requirement.